Pioneers in Innovative Aquaculture Technology

Huizhou Fengwo Aquaculture Equipment Co., Ltd. (YUTANK) specializes in the R&D, manufacturing and export of recirculating aquaculture systems, committed to promoting aquaculture towards "industrialization, high-density, intelligentization and eco-friendliness".

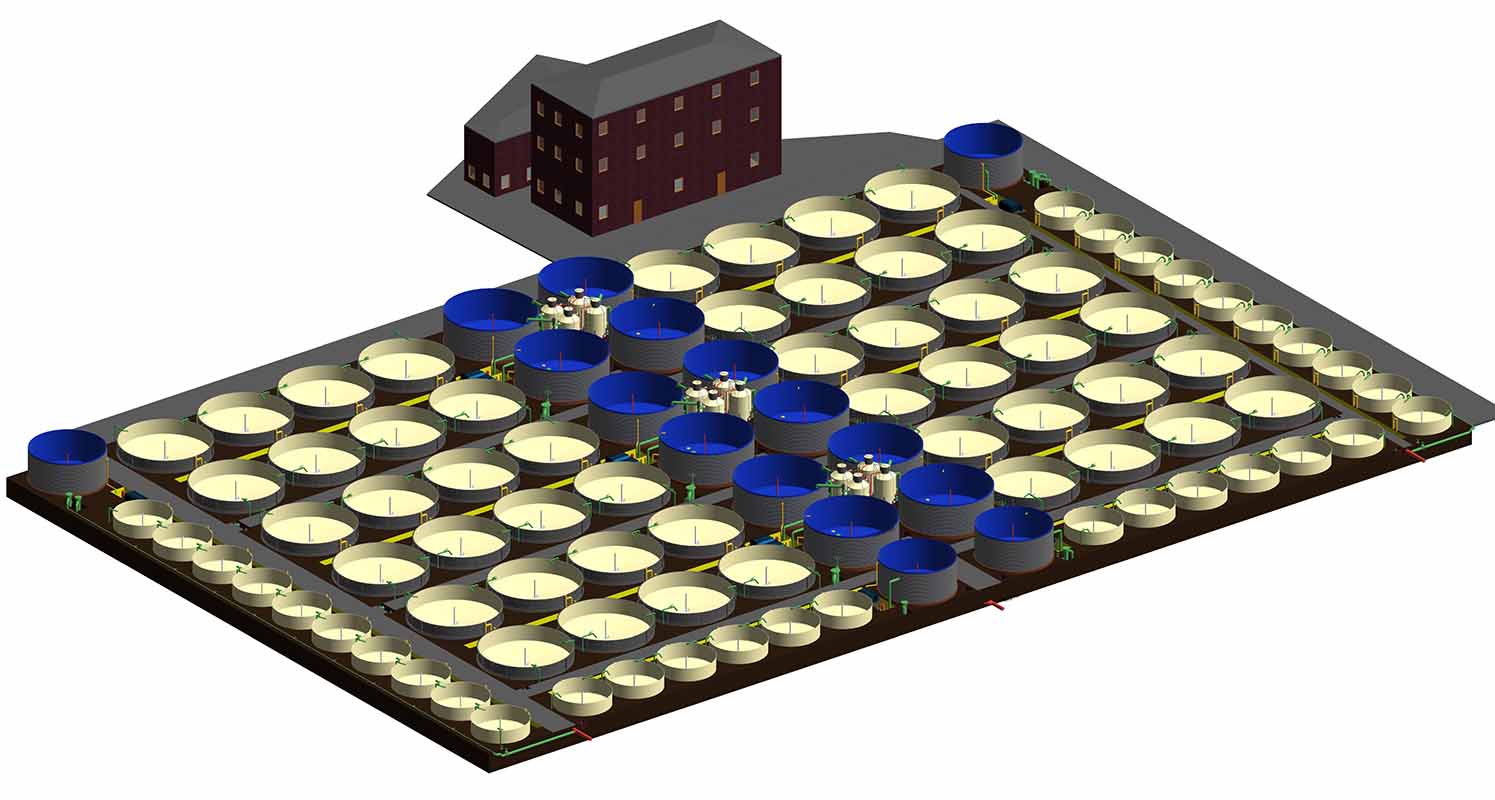

Comprehensive Pilot Project for Rural Revitalization through Recirculating Aquaculture in Jiangshan City, China

Project Name: Comprehensive Pilot Project for Rural Revitalization through Circular Aquaculture in Jiangshan City

Planned Completion Date: October 2024

Project Location: Jiangshan City, Daxi Town, Hekeng Village

Project Scope:

Total land area: 500 mu (approx. 33 hectares)

Total investment: 80 million RMB

Project Highlight:

Builds the region’s largest integrated recirculating aquaculture system (RAS) base with constant-temperature facilities

Specializes in antibiotic-free fish farming

Aims to dominate high-end aquatic product markets in Jiangshan and surrounding regions

Phase Targets:

By August 2026: Annual output of 1,250 tons of market-size fish

By end of 2025: Annual production capacity reaches 2 million fry (juvenile fish)

Technology Output:

By end of 2026: Annual sales of 30 million fry, generating output value of 15 million RMB

Technological Breakthroughs:

Developed Jiangshan’s first automatic RAS nursery system

Broke through key technical barriers in constant-temperature breeding

Antibiotic-Free Certification:

Achieves green, eco-friendly breeding by eliminating antibiotics

Targets certification from third-party international food safety organizations

High Survival Rates:

Fry survival rates ≥ 95%

Adult fish survival rates ≥ 80%

Per-mu output increased 3× compared to traditional methods

Fry Tanks:

18 tanks

Diameter: 6m × 1.5m deep

Total volume: ~550 cubic meters

Juvenile Fish Tanks:

27 tanks

Diameter: 6m × 1.5m deep

Total volume: ~830 cubic meters

Adult Fish Tanks:

308 tanks

Diameter: 8m × 1.4m deep

Total volume: ~22,000 cubic meters

Economic Benefits:

Total investment for Phase 3 is projected at 15 million RMB

Per-mu output value far exceeds traditional extensive farming

Industrial Value:

Builds a benchmark RAS facility with "efficiency, environmental sustainability, and zero antibiotics"

Model for industry technology demonstration and technical training

Market Value:

Serves as a supply chain base for mid-to-high-end aquatic products

Fills market gaps for antibiotic-free farmed fish

Meets growing consumer demand for green, safe protein

“After using 150 units of the constant-temperature equipment provided in Phase 1, with each unit costing around 10,000 RMB and achieving antibiotic-free aquaculture results, we’re confident in expanding across the entire site. Once the base is completed, it will significantly reduce our mortality rates and improve yield across all categories of freshwater fish.”

— Project Manager, Jiangshan Aquaculture Base

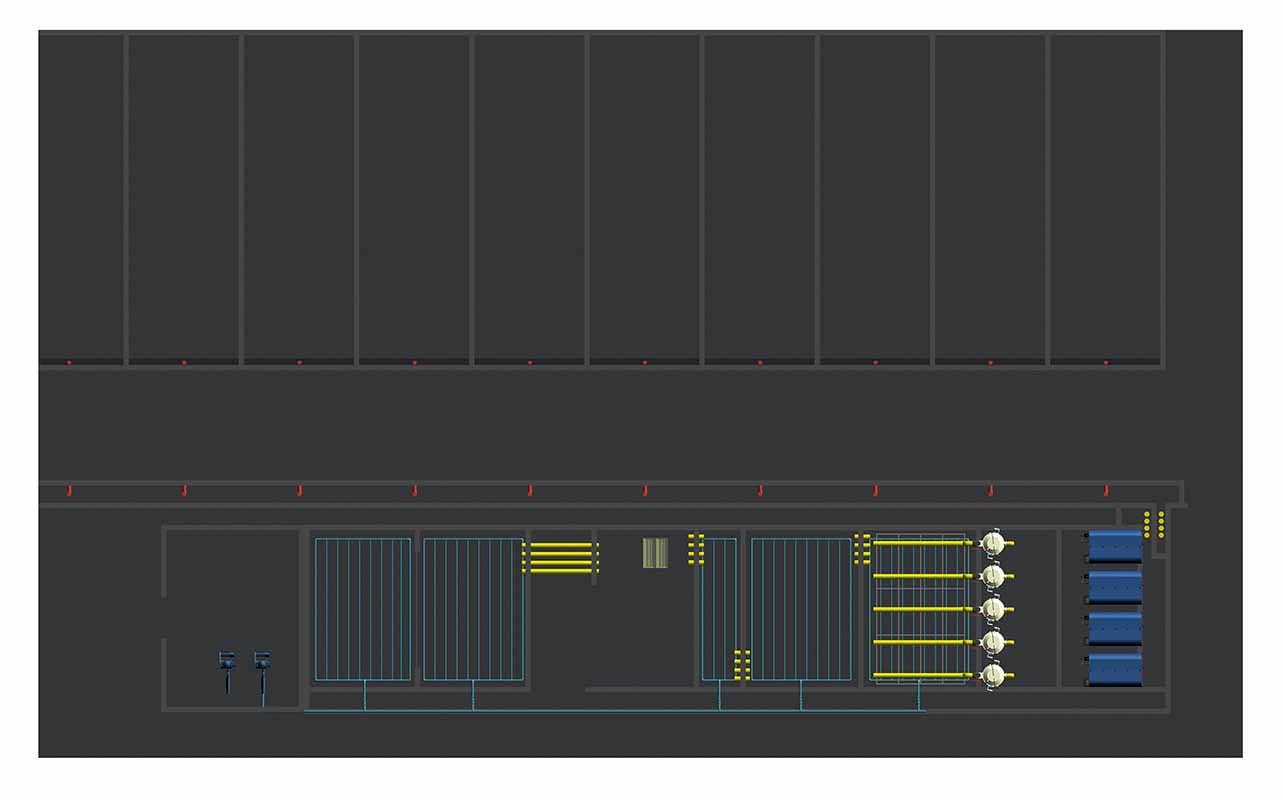

Riyadh Tilapia RAS System — Existing Site Retrofit Project

Project Name: Riyadh Tilapia RAS system retrofit project.

Project Schedule: Construction started July 2025; completed September 2025.

Location: Riyadh, Saudi Arabia.

Project Scale / Investment: 3,000,000 (unit as stated in source: “300万”).

Project Challenges: Severe scarcity of water resources in Saudi Arabia; high groundwater salinity; ambient temperatures reach up to 45°C; surrounding infrastructure is incomplete — making construction difficult.

Scale of Farming: Successfully converted and upgraded to a recirculating farm exceeding 2,500 m³, consisting of 25 concrete rectangular tanks of 100 m³ each.

Expanded Production Density: Stocking density increased from the original 20 kg/m³ to 50 kg/m³.

Design Breakthrough: Completely solved problems related to sewage/discharge difficulties in rectangular tanks; water ammonia and nitrogen levels significantly reduced.

Environmental Breakthrough: Successfully achieved high-density tilapia farming under 45°C high-temperature conditions.

System Customization: System engineered and customized for Saudi local conditions — geography, climate, and water source — delivering a tailor-made farming solution.

Stability & Resilience: Effectively resists high-temperature stress; maintains stable water quality and system performance.

Efficiency Optimization: Addresses the pre-existing issues of low production capacity, poor water quality, and discharge/dumping difficulties; realizes high-density aquaculture and improved operational efficiency.

Rapid Payback: Investment payback period is only one year; the owner is extremely satisfied with the retrofit results.

Strategic Impact: The RAS solution resolves local water-resource constraints for Saudi fisheries; the project has gained government-level promotion/support.

“This RAS farm was originally designed by another company, but the stocking density remained stuck at 20 kg/m³. In March this year, our engineers visited the site, identified numerous design shortcomings, and proposed retrofit solutions. We fully endorse their recommendations.”

— Project Lead, Riyadh Project

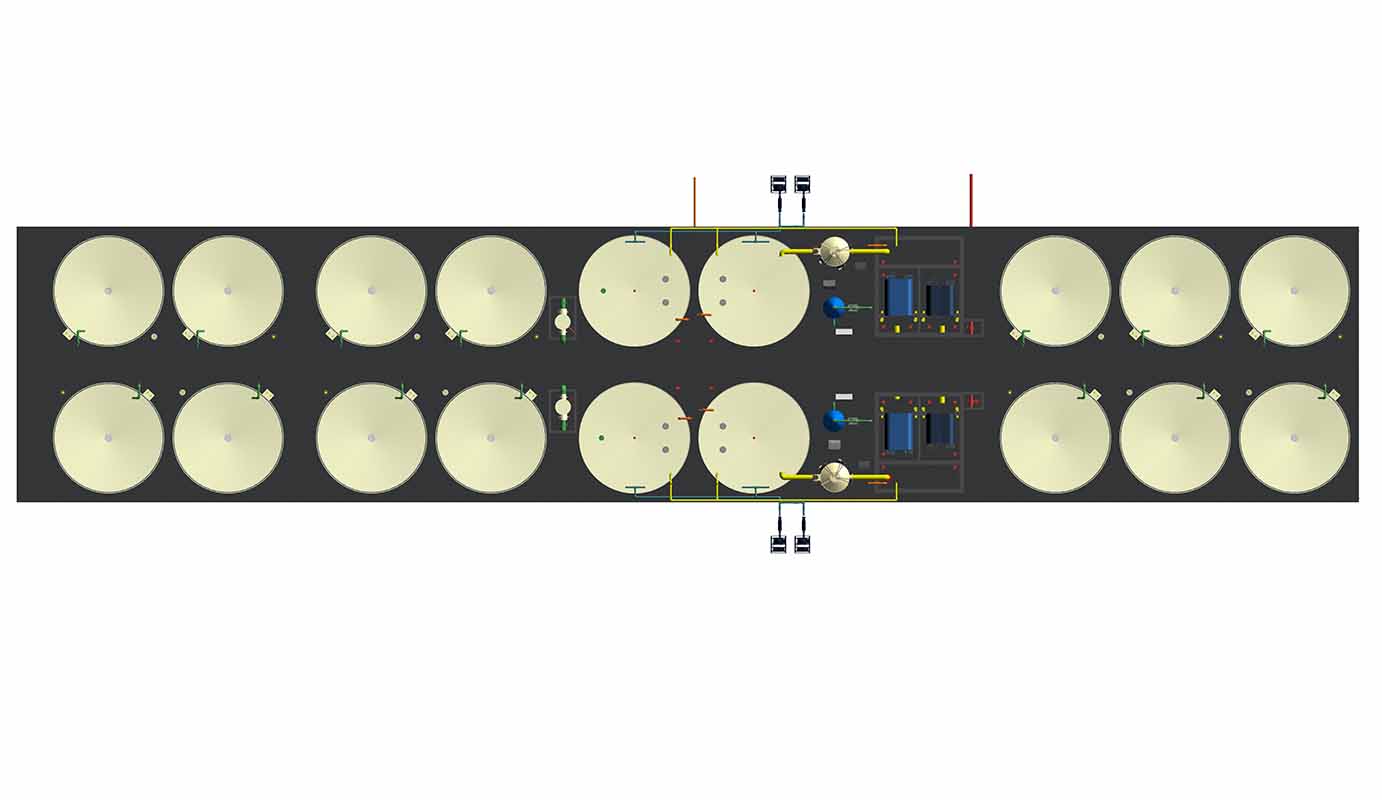

Small-scale Recirculating Aquaculture System (RAS) demo center for tilapia in Brazil

Project Name: Brazil — Tilapia Small-Scale Recirculating Aquaculture (RAS) Demonstration Center.

Project Date / Location: July 2025 (São Paulo region, Brazil).

Project Scale: 2,000 m³ total system capacity.

Project Challenges / Objectives:

Technical verification: Demonstrate high-density tilapia culture (target 80 kg/m³), healthy production and collect critical performance data.

Exhibition & demonstration: Serve as an RAS case study to visually demonstrate the advantages of recirculating aquaculture to visitors and potential clients.

Experience accumulation: Provide design, management and operation benchmark data for subsequent large-scale commercial farms.

Investment guidance: Reduce upfront trial-and-error costs; use a small, successful demonstration to drive follow-on cooperation and scaling.

Integrated design: Compact, easy to install and commission; space-saving layout facilitates future expansion.

Intelligent control: Onboard data acquisition and remote monitoring capabilities, supporting real-time adjustments.

Strong adaptability: System depth, circulation and temperature control are designed to meet customer plans and to suit high-density culture requirements.

High resource efficiency: Recirculating water treatment reduces freshwater usage while increasing output; centralized management improves operational efficiency.

Pilot objectives: Validate RAS stability and stocking performance under tropical climate conditions; collect tilapia growth curves and water-quality management data to support scale-up beyond 2,000 m³.

Expected pilot benefits:

Low-capital start: Small system lowers early-stage capital pressure.

High demonstration value: Functions as a living display site for RAS technology to attract prospective customers.

Replicable model: Once validated, the system can be rapidly replicated across multiple Brazilian sites for faster rollout.

Using modular calculations + data-driven management the system achieves:

Resource integration & optimization: Improve water use efficiency and reduce operating costs.

Environmental friendliness: Lower freshwater consumption and reduce environmental pollution.

Training & demonstration integration: Serve as a training base to raise local farmers’ technical skills and operational capability.

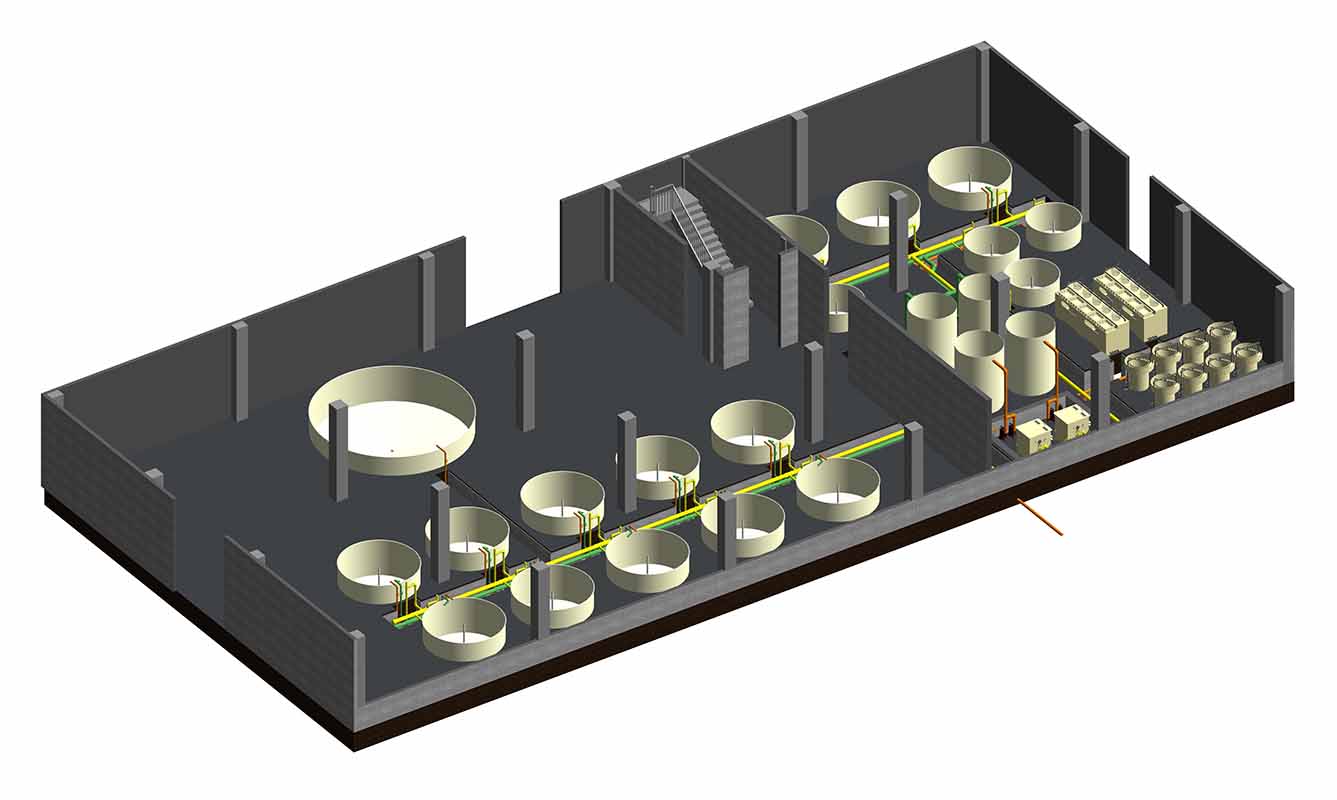

Vietnam Seafood Factory RAS Farming System Project

Factory-style Recirculating Aquaculture System (RAS) for seafood (sea cucumber / shrimp / king crab, etc.)

Project Name: Vietnam factory-style recirculating aquaculture system for abalone, freshwater shrimp, king crab and other seafood.

Project Schedule: August – October 2025.

Project Location: Vietnam — seafood wholesale / processing company site.

Project Scale: Six integrated RAS units (six-group integrated recirculating aquaculture systems).

Project Challenge: Maintain low-temperature culture and meet stringent water-temperature and water-quality requirements for the target species.

The client aims to build a leading high-value, green aquaculture base in Vietnam. The objective is to raise stocking density, stabilize water quality and annual production capacity, and at the same time meet international product control and export standards.

Support high-density culture for multiple species including king crab and freshwater shrimp.

Realize automatic control of key parameters such as water temperature, dissolved oxygen and pH.

Possess highly efficient physical filtration and biological purification capabilities to minimize water exchange.

Compact, highly integrated system design to fit constrained site footprints.

Provide timely alarms/alerts to farmers when water quality or oxygen levels deviate from set thresholds.

Compact integrated design: All equipment modules (physical filtration, biological treatment, oxygenation, temperature control and sterilization) are consolidated—saving more than 30% of site area.

Intelligent control: Real-time monitoring and automatic regulation ensure the sensitive water-quality needs of king crab and shrimp are met; supports mobile remote monitoring and alarm functions, lowering labor costs while improving operational security.

Green & energy efficient: Water reuse rate ≥ 90%, reducing freshwater consumption and effluent; high-efficiency aeration and low-energy pump design lower overall energy use by approximately 25%.

Quality control assurance: Multi-stage water purification and disease-prevention controls secure water stability and meet export-level farming standards, supporting supply to high-end markets.

Efficiency value: Complete delivery and commissioning of the six-unit system within 30 days, shortening typical industry cycle times by ~50% and enabling rapid market capture.

Quality value: Through systematic water-quality management, projected improvements include +20% survival rate, +15% feed-conversion optimization, and ~30% annual production increase.

Cooperation value: This project will serve as a benchmark case for our company in Southeast Asia’s high-end aquaculture sector and provide a foundation for promotion to markets such as Thailand and Sri Lanka.