Microfiltration Systems Update: New Technologies in 2025

- denghao

Table of Contents

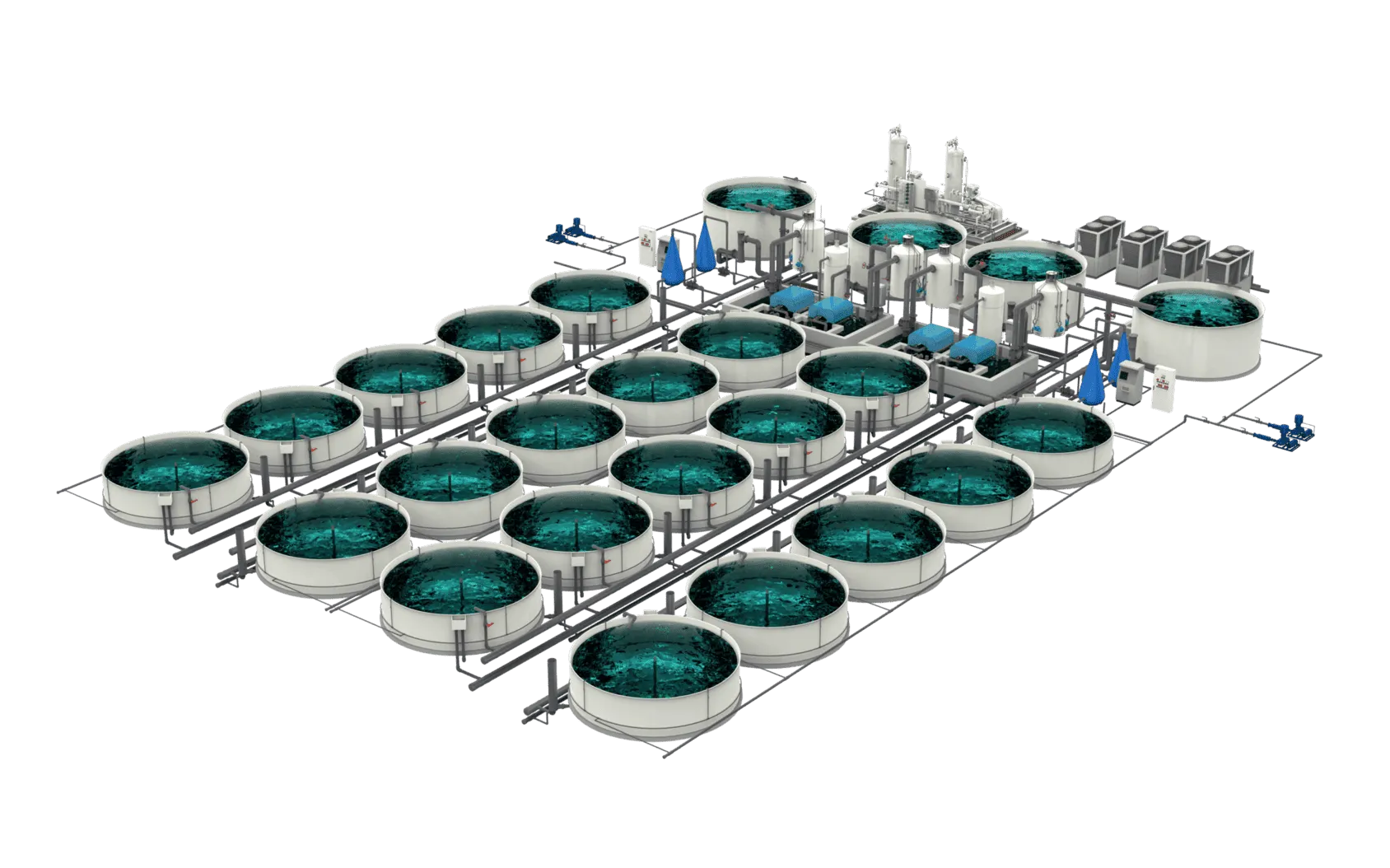

Running a recirculating aquaculture system (RAS) without reliable microfiltration systems is like trying to keep your living room clean during a toddler’s birthday party—chaotic, messy, and bound to end in heartbreak. Dirty water doesn’t just threaten fish health; it eats away at your energy bills, membrane lifespan, and sleep schedule.

Some farmers are still clinging to outdated tech that fouls up faster than a mud wrestle on a rainy day. “We saw up to 30% less energy use after switching membrane modules,” says Elena Maoré, lead R&D engineer at Yutank Systems (Q1 2025 Report). That’s not small potatoes—that’s real savings.

In 2025, the new wave of filtration gear doesn’t just filter—it thinks. Real-time sensors? Check. Anti-fouling crossflow setups? Double check. It’s the kind of upgrade that makes you wonder how you ever farmed without it.

If you’re juggling shrimp tanks or coaxing tilapia through another growth cycle, this update could be your next big break—because cleaner water isn’t optional anymore; it’s mission-critical.

Reading Notes for Energy-Smart Microfiltration Systems in 2025 Aquaculture

➔ Power Savings from Pressure Control: Crossflow membrane modules, when optimized for transmembrane pressure, can reduce energy use by up to 30%, thanks to improved flow dynamics and minimized resistance.

➔ Flux Rate Matters: Automated backflush filters that are tuned for optimal flux rates clean more efficiently, cutting down on overall system power demands.

➔ Pump Smart with Polymers: Pairing polymeric membrane systems with low-energy filtration pumps reduces both operational costs and environmental impact.

➔ Durability Meets Efficiency: Ceramic membranes housed in thermally efficient materials enhance longevity while minimizing heat loss—ideal for demanding aquaculture environments.

➔ Water Reuse That Works: Microfiltration systems help improve recirculation loop efficiency and water quality across species like shrimp and tilapia, making continuous reuse sustainable.

➔ Monitoring Makes the Difference: Real-time pressure sensors and automated particle counters provide constant insights, helping prevent fouling before it drains resources or harms fish.

How 2025 Microfiltration Systems Reduce Energy Use By 30%

New-age filtration setups are shaking up the old rules—cutting power bills and emissions while keeping things squeaky clean.

Crossflow Membrane Modules: Optimizing Transmembrane Pressure for 30% Less Power

This isn’t just about turning knobs—it’s about tuning flow like a maestro. Dialing in transmembrane pressure changes how liquid moves across membranes, slashing resistance and boosting efficiency. Here’s how it plays out:

- Lower pressure differentials reduce pump strain, directly cutting energy draw.

- Smart sensors help maintain ideal pressure zones in real-time.

- Adaptive control systems tweak flow rates based on fouling levels or throughput needs.

These tweaks don’t just save juice—they extend membrane life too. That means fewer replacements, less downtime, and better system efficiency improvements all around.

Flux Rate Optimization in Automated Backflush Filters

Getting the flux rate right is like finding your car’s fuel sweet spot—it’s all about balance. Pushing water through too fast? You’ll waste energy. Too slow? You clog up faster than rush hour traffic.

- Set baseline flux using historical fouling data from similar operations.

- Automate adjustments based on turbidity and inflow variability.

- Integrate predictive cleaning cycles to reduce unnecessary backflushing.

By optimizing these variables, operators can keep things flowing without overworking pumps or filters—essentially squeezing more performance out of every watt used during membrane filtration processes.

Polymeric Membrane Systems with Low-Energy Filtration Pump Selection

Choosing the right pump isn’t glamorous—but it’s where real savings happen. Especially when dealing with polymer-based membranes that don’t need brute force to function well.

Grouped insights:

- Pump Type Matching

• Centrifugal pumps suit low-viscosity fluids.

• Positive displacement pumps work better under variable loads. - Energy Ratings & Efficiency Curves

• Look for motors with IE5 ratings or above.

• Match operating points to peak efficiency zones—not max output. - Integrated Variable Speed Drives

• Adjust flow dynamically without wasting power at off-peak times.

Pairing smart pumps with flexible polymeric setups creates measurable drops in operating costs—boosting both sustainability and bottom-line results through smarter energy consumption reduction strategies.

Ceramic Membrane Filtration and Membrane Housing Materials for Energy Savings

Ceramic filtration tech has come a long way—and now it’s not just tough but also chill… literally. These materials handle heat like champs but also prevent thermal bleed-off that drains energy fast.

| Material Type | Thermal Conductivity (W/m·K) | Energy Loss Rate (%) | Durability Rating |

|---|---|---|---|

| Alumina Ceramics | 25 | <5 | High |

| Titanium Oxide Mixes | ~18 | ~6 | Very High |

| Polymer Composite | <0.2 | >15 | Medium |

When paired with insulated housings made from stainless steel alloys or composite shells, these setups minimize heat loss during continuous runs—making them ideal for high-volume industrial water treatment applications where every kilowatt counts toward meaningful cost savings analysis and reduced environmental impact assessment metrics.

Types Of Microfiltration Membranes

A quick dive into the four main types of membrane setups used in small-pore fluid filtration—each with its own perks and quirks.

Hollow Fiber Microfiltration Modules

• These skinny tube-like membranes pack a punch thanks to their ultra-high surface area, making them ideal for filtering out bacteria and other nasties from water or air.

• They’re super compact—great when space is tight—and can handle large volumes without needing constant attention.

• Most are made from polymeric membranes, which keeps costs down while still delivering decent durability.

• Common in municipal water treatment, lab-scale purification, and even some food & beverage processes where fine particle removal matters most.

• Because of their geometry, they’re also easy to scale up or down depending on the job at hand, giving engineers flexibility in system design.

Ceramic Membrane Filtration Advancements

These aren’t your average filters—they’re built tough using ceramic membranes, which means they can take heat, pressure, and aggressive cleaning chemicals like champs. That’s why industries dealing with oily wastewater or high-temperature fluids are leaning into this tech more than ever. According to Bluefield Research’s 2024 Water Tech Outlook, demand for ceramic units has surged by over 18% year-over-year as industrial users seek longer-lasting alternatives to traditional polymer setups. Their rigid pore structures offer consistent results even under stress—so if you need something that won’t flinch when things get rough, ceramics are worth a look.

Polymeric Membrane Systems Characteristics

→ Materials:

- Polymeric membranes such as PVDF and PES dominate due to low production cost.

- Easily modified chemically to suit different filtration jobs.

→ Pore Size Control:

- Adjustable during manufacturing; lets engineers target specific contaminants.

- Widely used in biotech labs where precision matters.

→ Applications:

- Municipal water systems

- Food-grade processing

- Biopharma separation tasks

→ Pros:

- Lightweight and versatile

- Good chemical resistance when treated properly

→ Cons:

- Limited lifespan under harsh conditions

- Susceptible to fouling if not maintained correctly

Thanks to their balance between performance and price point, these systems remain the go-to option across many types of micro-scale filtration needs.

Crossflow Membrane Module Configurations

Step 1: Fluid enters tangentially across the membrane surface instead of directly through it—that’s what sets crossflow designs apart from dead-end setups.

Step 2: As liquid flows along the surface, smaller particles slip through pores while larger ones stay suspended in motion above it. This movement helps prevent clogging—aka fouling—which is a major headache in stationary filters.

Step 3: The retained material gets concentrated over time while clean filtrate exits separately. This setup is especially handy when working with slurries or high-solids liquids that would otherwise choke standard filters fast.

Crossflow modules often use either composite membranes or advanced forms of polymeric membranes, depending on what’s being filtered. They’re widely used in dairy processing, pharmaceutical prep lines, and even semiconductor rinse systems where purity is non-negotiable.

3 Stages Of Membrane Cleaning Protocols

A good cleaning protocol is like a tune-up for your filtration setup—it keeps things humming and extends membrane life.

Stage 1: Low-Pressure Backflush for Suspended Solids Removal

• Gently dislodges particles without stressing the filter surface

• Ideal for early-stage fouling, especially from dust, silt, or grit

• Helps stabilize flow rate before more intensive steps kick in

Grouped into routine maintenance schedules, this low-pressure rinse clears out the bulk of suspended debris that would otherwise choke performance. Especially with pretreatment systems lagging or inconsistent feedwater quality, this step becomes a front-line defense. Operators using pressurized backflush on micro + filtration modules typically report fewer instances of sudden flux drops—no surprise since it’s all about keeping that initial layer off the membrane face.

Stage 2 Alkaline Soak Targeting Organic Matter Reduction

Once solids are flushed out, it’s time to deal with sticky organics that cling on tight:

- Mix an alkaline solution between pH 10–11 to break down fats and proteins

- Soak membranes for at least 45 minutes at a controlled temperature (~35°C)

- Rinse thoroughly post-soak to prevent chemical carryover

This stage often calls for specialized cleaning agents, such as non-foaming detergents designed specifically for polymeric membranes in fine pore filters. The soak targets biofilms and oily residues that sneak past basic rinses—especially common in food-grade or high-organic wastewater streams where organic loading is heavy even after upstream pretreatment.

📊 Table: Recommended Parameters for Alkaline Soaking by Membrane Type

| Membrane Material | pH Range | Temp (°C) | Soak Duration (min) |

|---|---|---|---|

| PVDF | 10–11 | 30–40 | 60 |

| PES | 9–10 | <35 | 45 |

| PAN | Up to 11 | ~35 | ≥50 |

This data reflects typical conditions used in industrial micro + filtration setups across beverage and biotech sectors.

Stage 3 High-Pressure Flushing to Mitigate Membrane Fouling

When grime gets stubborn, it’s time to bring out the big guns—high-pressure flushing resets permeability by blasting away hardened deposits stuck deep within the pores. This isn’t just about brute force though; pressure has to be balanced against fragility, especially with thin-film composite membranes used in advanced microfiltration arrays.

Operators should monitor flow rate closely during this step and adjust based on resistance readings. Combine this with tight control over cleaning frequency and consistent performance monitoring, and you’ve got a recipe for longevity—even under harsh operating cycles.

Yutank recommends pairing high-pressure flushes with smart diagnostics tools built into their controller kits—letting users track fouling trends while optimizing cleaning intervals automatically through AI-based scheduling logic built right into their firmware platform.

Aquaculture: Continuous Water Reuse With Microfiltration Systems

Reusing water smartly keeps aquaculture efficient, clean, and cost-effective—especially when you’ve got the right filtration setup on your side.

Shrimp Farming Applications: Turbidity Control and Automated Particle Counting

Getting shrimp ponds to stay clear without constant intervention is a tall order—but with smarter turbidity control tools, it’s totally doable.

- Turbidity sensors now work hand-in-hand with automated particle counters, giving real-time updates that help farmers adjust aeration or filtration instantly.

- These systems flag suspended solids before they affect fish health, especially during feed-heavy periods.

- Some setups even use AI to predict spikes in cloudiness based on feeding schedules or weather patterns.

- Daily monitoring has gone from manual guesswork to screen-based precision—less time wading, more time optimizing.

- With better visibility into water clarity, shrimp show improved growth rates and stronger immunity against pathogens.

- By combining fine-pore membranes with UV pre-treatment, farms can hit both pathogen removal and clarity targets.

Enhancing Recirculation Loop Efficiency in Tilapia Culture Systems

Tilapia thrive when their environment stays stable—and tight recirculation loops make that possible while slashing water waste.

• High-efficiency pumps reduce energy draw while keeping flow rates ideal for oxygenation.

• Smart loop designs minimize dead zones where waste accumulates.

• Inline biofiltration units break down ammonia fast, boosting survivability during high-density stocking.

Grouped Improvements:

— Mechanical upgrades like variable-speed drives cut costs by adapting to load demand.

— Biological tweaks such as increased surface area media improve nitrification efficiency.

— Operational practices like staggered backwashing keep the system running without downtime.

Together, these tweaks form a closed-loop system that’s not just sustainable—it’s profitable too.

Real-time Pressure Sensors for Marine Finfish Aquaculture Monitoring

When raising marine finfish like sea bass or cobia, keeping an eye on pressure changes inside tanks isn’t just helpful—it’s essential.

- Pressure sensors tucked into pipe junctions offer second-by-second tracking of flow disruptions or blockages.

- This data helps spot early signs of membrane fouling or pump failure before it snowballs into a crisis.

- A sudden dip? Might be a leak downstream. Spike? Could mean clogged filters or fish crowding near outlets.

- Operators can set alerts tied to pressure thresholds so no one misses a beat—even overnight shifts stay informed.

- These insights also support smarter scheduling of filter cleaning cycles, leading to longer-lasting microfiltration membranes and lower maintenance costs overall.

- As one recent report from AquaTech Metrics noted in early 2024, “Facilities using real-time pressure analytics saw up to 12% fewer fish losses linked to water quality issues.”

Membrane Housing Materials and Piping Configuration for Reduced Water Consumption

It’s wild how much difference the right pipes and housings make—not just in durability but also in cutting down how often you need fresh top-ups.

• Material choice matters big time: stainless steel resists corrosion but costs more; PVC is cheaper but needs extra reinforcement under heat stress.

• Compact housing cuts dead space where stagnant water might sit—a win for both hygiene and flow rate consistency.

Grouped Design Choices:

– Modular pipe layouts allow easier upgrades if scaling up production later becomes necessary.

– Sloped return lines improve gravity-fed drainage during system purges, reducing manual labor hours.

– Insulated pipes help maintain temperature stability across long runs—key for sensitive species like trout.

By tightening up plumbing design around your filtration unit—from intake all the way through discharge—you’re not just saving water; you’re upgrading your entire operation’s sustainability profile with brands like Yutank leading the charge toward smarter infrastructure choices.

FAQs about Microfiltration Systems

How do microfiltration systems improve water quality in recirculating aquaculture setups?

Clean, stable water is the heartbeat of any RAS operation. Microfiltration systems act like a silent workhorse—removing bacteria that sneak through biofilters, stripping out suspended solids before they clog up your tanks, and keeping turbidity low so fish can thrive stress-free. These systems don’t just polish the water—they protect your entire investment.

Why does transmembrane pressure matter when it comes to energy use?

- Lower pressure means less strain on pumps

- Less resistance = smoother flow across membranes

- Reduces electricity costs by as much as 30%

Dialing in the right transmembrane pressure isn’t just technical—it’s smart economics for long-term sustainability.

Can polymeric membrane units adapt to different species and system designs?

Absolutely. Whether you’re raising shrimp in brackish raceways or tilapia in freshwater loops, these membranes flex with your needs. Their customizable pore sizes let you fine-tune filtration based on species waste output and feeding habits—so you’re not over-filtering or under-protecting.

What makes ceramic membranes such a sustainable option for serious operators?

Ceramic modules are built to last. Their heat tolerance allows high-temp cleaning without damage, which cuts down on chemical use and keeps operations cleaner overall. They also resist fouling better than most polymers—which means fewer replacements and lower maintenance bills year after year.

How do automated backflush filters stay efficient over time?Backflushing sounds simple—but timing is everything.

- Keeps flux rates steady by removing buildup early

- Avoids sudden drops in performance during peak load

- Minimizes downtime since cleanings happen automatically

It’s a quiet guardian behind-the-scenes, making sure things never spiral out of control.

Which monitoring tools help adjust filtration settings quickly when conditions shift?When solids spike or flow slows unexpectedly, real-time sensors step in fast:Pressure monitors catch clogs before they cause chaos; particle counters track how much debris is building up; turbidity meters give instant feedback if clarity dips below safe levels—all working together so you can react before problems become disasters.